Table of Contents

6.1

...

Print string marking

All ENDUROWALL® parts are coded with information to assist erectors in the assembly process. This matches the part information shown on the assembly drawings.

All ENDUROWALL® parts Parts are coded in the following order:

Job Name/NumberId, Frame Number, Part Number and Part Usage. For short parts, some of this information is deleted.

With this information, erectors can identify what the part is and where it is intended to be used in the structure. The illustration below shows how the coding works:

Figure 6.1 Marking and branding

Job name/number is Test Walls

In the above example, the job id is "Test_walls", 5 is the panel number, 001 is the part number and Topplate TOPPLATE is usage.

Figure 6.2 A typical wall frame assembly sheet as produced by ENDUROCADD®. The sections are branded when produced in accordance with Section 6.1 of this manual.

...

Newer walls have a usage identifier rather than the full usage description and may have additional information such as the part length. It is still very easy to identify the usage using the following table:

| Identifier | Usage |

|---|---|

| TP | Top Plate |

| BP | Bottom Plate |

| HEAD | Header |

| SILL | Sill |

| STUD | Stud |

| NOGG | Nogging |

6.3 Assembly Procedure

ENDUROWALL® is generally factory assembled or assembly by a third party from completely knocked down (CKD) packs. The following illustrations show the typical steps for site assembly of a wall frame.

6.3.1 Preliminary work

It is important that you check all components delivered on-site against your 'Delivery Packing List' to ensure complete delivery.

Step 1 Part Identification

Unpack the frames and sort frames into frame lots using the branding as a manual. Identify the studs from the branding information on the parts.

Wall & truss framing will be plastic wrapped & labelled in bundles as registered on packing list

Wall frames are individually strapped & stacked in "stud" bundles, labelled with bundle numbers

Matching frames in "nogging, top & bottom plate" bundles, labelled with bundle numbers

Accessories will be consolidated on pallets or in boxes as registered on the packing list.

Accessories bundles to be checked upon delivery.

Sort & stack all accessories, cross check packing list. (helps to mark on box's, where accessories are to be used)

...

Step 1

Identify the studs and lay toes down on a level surface and align as per assembly drawing. The heads, sills and noggings should be pre-notched allowing parts to overlap as shown. Pre-punched holes are provided for trilobular fastener screws to connect the frames.

Locate & and open matching stud & and nogging / plate bundles before separating into individual frame packs.

Separate and move stud & nogging / plate frame packs next to designated assembly zone.

Lift & and separate stud pack onto assembly table (this example has utilised Topspan® 40 sections on concrete block stacks as an assembly table).

Step 3 - Prepare bent tab studs

Identify and separate Endurotie® bent tab studs (90mm system only)

. The Endurotie® bent tab studs can be identified by the extension of the stud web section and double15mm hole punch for insertion of a frame anchor bolt (or similar). Prepare bent tab studs

•

- Place the stud with the web down.

...

- With a small cold chisel and a hammer, flatten the ribs on the rib in line with the stud flange.

...

- With a pair of duck bill pliers, bend the tab in the appropriate direction. (Refer to layout plan provided with job outputs.)

Layout all studs in sequential order, space out & orientate frame as per assembly sheet.

Fix all studs by inserting into top plate on approx. 45deg angle.

Align holes, fix at studs and install trilobular fastener.

Step

...

4 - Fix at Studs

When carrying out the primary assembly of the frame align notch holes as shown and install trilobular fastener in holes.

Align top of studs & screw fix top plate at both ends. (Where utilised, ensure Endurotie® bent tab studs are placed in the correct location and orientation.

Twist stud into position & align fixing holes – repeat for all studs along top plate.

Step

...

5 - Fix at corner and install

...

trilobular fastener

Align notch holes as shown and install trilobular fastener in holes.

Slide noggings onto the studs from base of frame & align fixing holes. May require 2 people to slide up studs evenly.

Fix bottom plate to studs, align holes & screw fix all noggings & bottom plate connections on "Side A". (Easier to fix bottom plate on an angle, starting at one end & pinching studs into plate, working along the frame). Ensure Endurotie® bent tab stud alignment is correct.

Nogging Installation

Step 6 - Install Noggings

Position each one over the frame near their final location. Nogging height is specified in the supplied ENDUROCADD® panel drawings with the reference line to the centre line of the nogging.

Nogging installation.

Step

...

7 - Fix both sides

In order to process walls efficiently, two assembly tables situated side-by-side allows walls to be flipped over so both sides can be fixed off.

Cross check "Side A" frame layout & connections as per assembly sheet. Utilizing sufficient labour, lift & flip frame for "Side B" screw fixings.

Ensure sufficient labour available on both sides of frame to flip safely.

By utilizing two adjoining assembly tables, wall fabrication can be optimized by preparing the next frame while screw fixing & and checking "Side B".

Step

...

8 - Marking wall frames and prepare for openings

Before inserting any bracing or lintels, check the overall dimensions of the frame against the supplied Assembly Sheet. Square the frame before installing any bracing.

Marking frames

Frames should be identified with panel number and the number of any adjoining walls at the appropriate locations. These marks should be applied to the side of the bottom plate.

Step 9 - Install Cross Bracing

Install cross bracing as per wall assembly sheet using the nominated number of screws.

Number Number each completed wall frame & and mark the bracing locations to top & base of frames as per assembly sheet.

Located

Locate the pre-cut notch and use tin snips to prepare the tab prior to installation. (This enables easy removal of bottom plate at openings after frame installation). After panel is checked for squareness, screw fix bracing strap to wall plates as per wall frame assembly sheet. Alternate bracing types are fixed in a similar manner.

Figure 6.3 - Connection details of diagonal tension strap bracingNote:

| Info |

|---|

70mm strap brace requires two tensioners. |

...

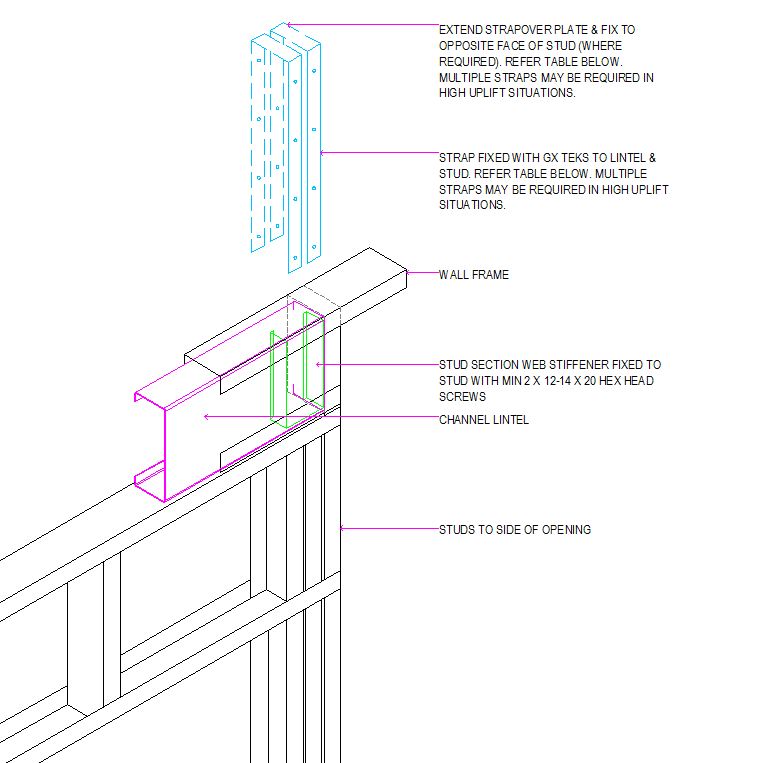

Step 7 10 - Install lintel flashing (where required)

Overlay & and screw fix lintel flashing to top of frame as per assembly sheet & and fixing details given in the Design Manual.

| Strap Size | Single or Double Sided | Straps | M6 Teks into Header and each Strap | M6 Teks into Jamb Stud and each strap |

|---|---|---|---|---|

| 30mm x 1.0mm | Single | 1 | 2 | 3 |

| 30mm x 1.0mm | Single | 2 | 2 | 3 |

| 50mm x 1.0mm | Single | 1 | 4 | 6 |

| 50mm x 1.0mm | Single | 2 | 4 | 6 |

| 30mm x 1.0mm | Double | 1 | 2 | 6 |

| 30mm x 1.0mm | Double | 2 | 2 | 6 |

FIGURE 6.17 - Beam Header Fixing Details

...

...

Step 11 - Stack completed wall frames before installation

Completed wall Relocate completed frames to be stacked in a flat designated stacking area ready for installation.

Stack wall frames in bundles close to the final installation position.

Ensure all wall frame locations have been set out on floor substrate before installation commences. Large wall frames may require additional stiffening to assist stability during installation process.

Always have a "plan of attack" when stacking wall frames. Locate frames in a central location, eliminating unnecessary man-handling & ease of installation.